Sand casting uses sand as the mold material, it is relatively cheap and sufficiently refractory and over 70% of all metal castings are produced via a sand casting process.

Suitable Materials:

Ductile Iron, Grey Iron, Aluminum, Brass.

We also do secondary operation including heat treatment and shot blasting. We have high technical force and can also machine the part after casting, we have got CNC machining center and CNC lathe equipment.

Basic Process:

1. Place a pattern in sand to create a mold.

2. Incorporate the pattern and sand in a gating system.

3. Remove the pattern.

4. Fill the mold cavity with molten metal.

5. Allow the metal to cool.

6. Break away the sand mold and remove the casting.

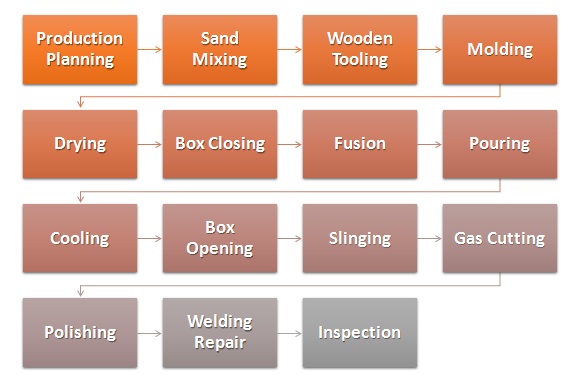

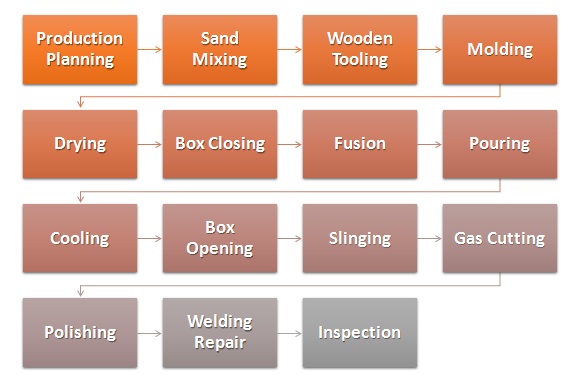

Production Procedure:

Clay Sand Casting:

Clay Sand Casting:

1. Low tolerance required products;

2. Low cost, simple procedure, short production life cycle;

3. Example products: automobile engine cylinder block, cylinder cover, crankshaft.

Resin Sand Casting:

Resin Sand Casting:

1. Provides a better surface quality;

2. Gives a higher tolerance control;

3. Suitable for middle and large sized casting parts.

Precoated Sand Casting:

Precoated Sand Casting:

1. Suitable for complex casting parts;

2. Provides a tighter tolerance control.

We also do secondary operation including heat treatment and shot blasting. We have high technical force and can also machine the part after casting, we have got CNC machining center and CNC lathe equipment.

Tags: Green Sand Casting | Resin Bonded Sand Casting | Aluminum Sand Casting | Brass Sand Casting | Copper Sand Casting | Grey Iron Casting | Ductile Iron Casting