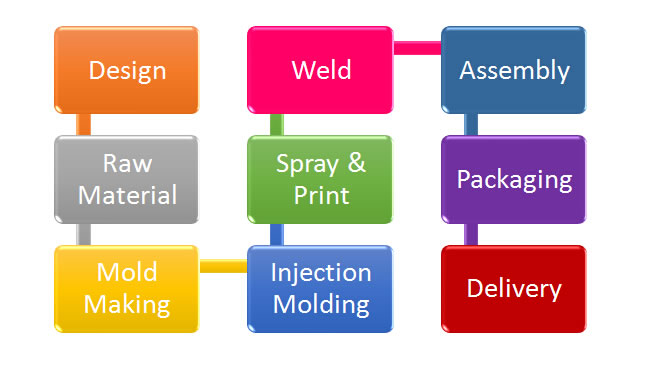

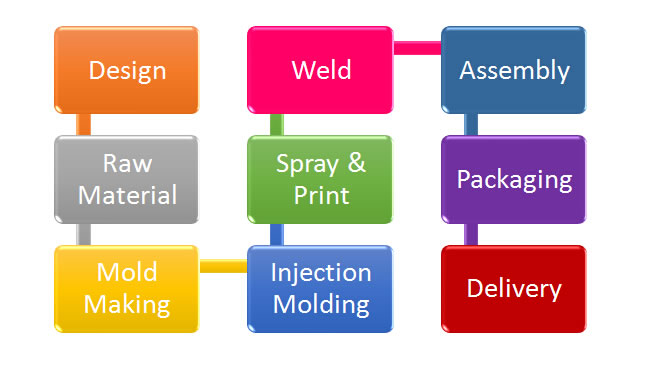

We focus on every single customer’s unique needs and match with the most appropriate plastic solution. Our capabilities are wide ranging and we can produce precision micro sized plastic parts and large injection molded parts up to 30 kgs. We make the plastic injection molds/tooling ourselves as well with decades experience. We are able to provide a one-package service, including design, mold making, painting, moldings, assembly, packaging, and delivery.

One-Stop Service:

We provide 4 types of Molding Service, depends on your order quantity:

We provide 4 types of Molding Service, depends on your order quantity:

1. Fast prototyping without mold cost, suitable for product design testing and quantity less than 50 pcs.

2. Small batch testing production run by low lifetime mold, suitable for low volume production less than 5,000 pcs.

3. Standard mold with over 200,000 shots lifetime for molding in our own facility.

4. Longer lifetime mold for export.

Certificates:

Our facility is ISO9001:2000, ISO/TS16949:2009, ISO14001:2004 and ISO13485:2003 certified and have great experience in supplying the US and the European markets, as well as Australian and Mexican markets.

Special Moldings:

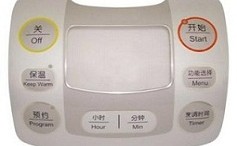

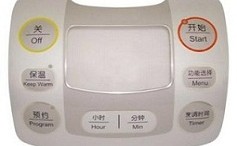

1.In-Mold Decoration (IMD)

1.In-Mold Decoration (IMD)

2.In-Mold Label (IML)

2.In-Mold Label (IML)

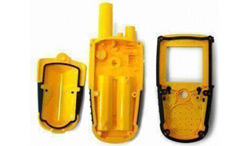

3.Insert Over Molding

3.Insert Over Molding

4.Dual-Color Molding

4.Dual-Color Molding

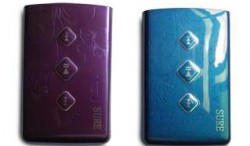

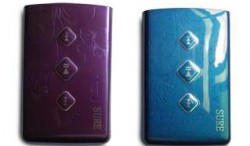

5.PEI High Smooth & Glossy Molding

5.PEI High Smooth & Glossy Molding

6.Sterilized Workshop with Constant Temperature for Medical and Cosmetic Parts

6.Sterilized Workshop with Constant Temperature for Medical and Cosmetic Parts

ISO 13485 Certified & UL Approved, Cleanroom Assembly (ISO 7 and ISO 8)

Secondary Process After Molding:

ISO 13485 Certified & UL Approved, Cleanroom Assembly (ISO 7 and ISO 8)

Secondary Process After Molding:

Printing: Hot Stamping/Decal, Silk-Screen Printing, Tempo Printing, Laser Engraving, Label Application

Assembly: Manual, Semi-Automated, Fully Automated, Cleanroom

Welding: Ultrasonic Welding, Vibration Welding, Laser Welding

Testing: Dimensional Testing (CMM), Leak Testing, Dielectric & Electric Testing, Optical Testing

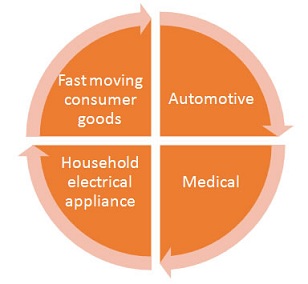

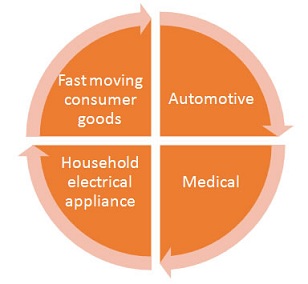

Product Range:

1.Automotive

2.Medical

3.Household electrical appliance

4.Fast moving consumer goods

Common materials used in injection molding:

PC, PS, PE, PVC, PE, PP, ABS, Rubber, Acetal

Common additives added into material:

UV inhibitors and Flame Retardants

Tags: Injection Mould | In Mold Decoration | In Mold Label | IMD Molding | IML Molding | Insert Molding | Outsert Molding | Plastic Overmolding | Injection Tooling