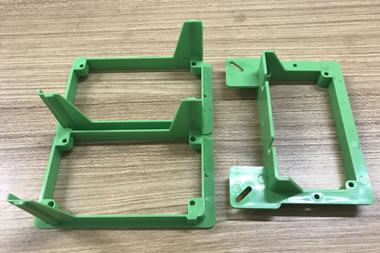

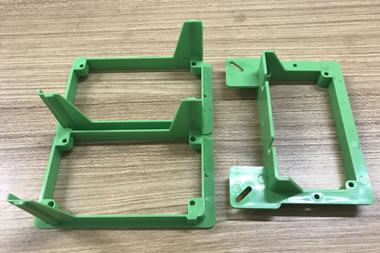

Injection Molding with Combined Mold for ABS Plastic Holding Speaker Parts

Customer Information and Requirement

An American customer sent us an inquiry which required three items been made by one single combined mold together in

August 2016. After accepting our price offer and confirming all the production details, we had the purchase order and started the mold production in September 2016.

We finished the mold production in one month time and made some samples, which were approved by our QC team, then we

sent them to the clients to confirm the quality.

The clients tested our samples in November and found out the designs for these 3 items actually needed to be changed

slightly. They sent us the updated drawings and we modified the mold accordingly.

By the end of December, we finished the mold modification and resent the clients new samples to confirm. These new samples were approved by the client this time and a production run order of 1,000 sets was placed to us in January 2017, which was finished in the same month, only took us 10 days to make.

Product Information:

(1) Product Name: Black-V4, Flap-V4 and Orange-V4

(2) Order Quantity: 2016 year 1000 kits

(3) Function: For holding speakers

(4) Material: ABS

(5) Production Progress: Injection Molding with Combined Mold of 1+1+1 Cavity

(6) Tolerance difficulty: must be able to assemble these three parts together, as well as assemble to the speaker’s main body.

(7) Surface Finish: Matte finish in green color, Pantone code 7488U.

(8) Quality System: ISO 9001:2008

(9) Production Due Date: 10 Days

(10) Package Information: Each carton size 42*50*48cm

(11) Gross Weight: 60 kg/carton